CAE Examples

We help our customers solve their issues through our services with technologies unique to us.

Example 1 : AZAPA Corporation

| Situation |

AZAPA Corporation is a company engaged in the research and development of core technologies and next generation services related to automobiles such as the development of automobile engine control. It had been considering creating a prototype of a personal transporter mounted with the control system it developed. Its name was "AZP-UDiS." The project started with the concept of "connecting the town and its people" through providing them with mobility in a form of device. |

|---|---|

| Issue(s) | They were looking for a company that could take on both the designing and analysis of structures to turn its project into reality. |

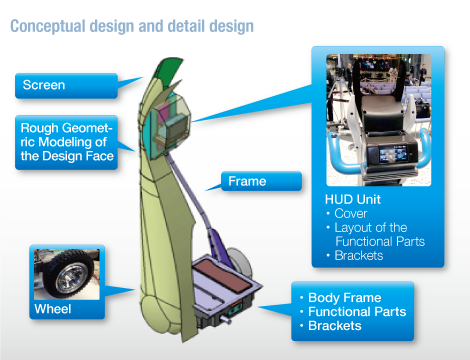

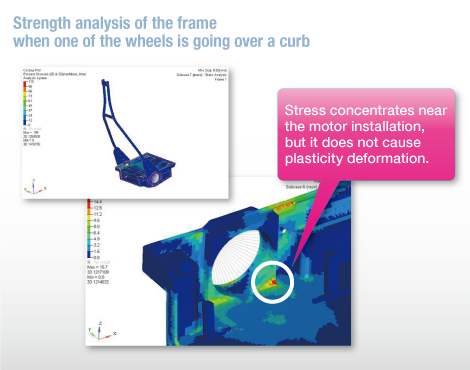

| Our Solution | We undertook the bulk of the development process, namely the conceptual design and detail design as well as strength analysis of the frame to turn the concepts into a tangible form.

We performed a strength analysis on the frame to grasp the characteristics of its strength and stiffness. We achieved weight reduction while maintaining the required strength.

|

Why Us

One of our strengths is being able to take on the majority of the development process from design to analysis.

Our services enable our customers to do the minimum amount of prototyping, which leads to shorter development time.

Result

"AZP-UDiS" was able to complete its first run on the road successfully.

Example 2 : Kokune Co., Ltd.

| Situation | Kokune Co., Ltd. is a casting component manufacturer that developed a unique casting method called "half cavity mold." The company was going to propose a new casting frame to a major machine manufacturer. |

|---|---|

| Issue(s) | The time until the proposal of the new frame was 1 week. For the proposal the company had requested a CAE analysis that satisfies the requirement of "minimizing the weight while maintaining the same stiffness as the current frame." |

| Our Solution | We considered the shape to be proposed based on numerical data produced by optimization analysis and static stiffness analysis. We successfully reduced the weight of the frame by 358 kg (approx. 26%) while ensuring the same stiffness as the current frame. |

Why Us

We possess knowledge and experience in "topology optimization" where the structure is optimized through trials and errors by freely changing the shape of the components etc. in order to achieve the required weight and strength.

We also have the advantage of being able to come up with practical design proposals by accurately interpreting the results of optimization analysis in order to turn ideas into a workable product.

Result

Customer comment: I feel that Chuozuken offered great value in terms of credibility in the analysis results. We will continue to work as partners and I hope we will be able to build a mutually beneficial relationship in doing so.

Service